Manufacturing punching and forming tools for injection molding and die casting means constantly coming up with new solutions to challenges with a wide range of tasks and processes. VERICUT gives you everything you need to simulate your NC program to avoid collisions and catch errors, gouges, and other potential issues. VERICUT's Force module optimizes programs to reduce cycle times and produce better surface finishes for your mold and die components.

Explore Resources and User Stories

-

iMFLUX Inc. User Story

Plastic injection moldmaking often means tough materials, complex geometries, and tight tolerances. Multi-cavity molds can sell for tens or even hundreds of thousands of dollars, which is why IMFLUX Inc. uses VERICUT Force to optimize their NC programs.

-

Great Plains Industries User Story

Reko International Group Inc. manufactures multiple types of molds both prototypes and production, as well as fixtures, special machines across multiple industries. In order to reduce lead time and increase efficiency and productivity, Reko chose VERICUT to simulate and optimize their machining process.

-

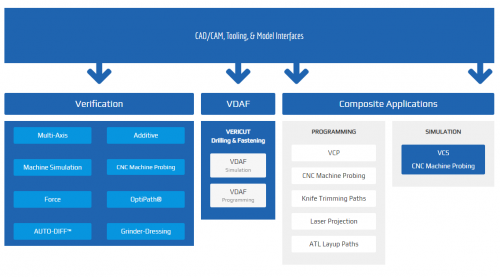

Explore Our Full Product Line

VERICUT offers solutions in machine simulation, verification, optimization, and more. Find the right modules to protect your CNC machines while increasing throughput.

-

VERICUT Force Optimization

VERICUT Force Optimization optimizes new and existing NC programs according to changes in cutting conditions. Protect your CNC machines and extend your tool life; watch the user story from Sandvik Coromant Mebane.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan