VERICUT Force

How to reduce machining times with VERICUT Force optimisation

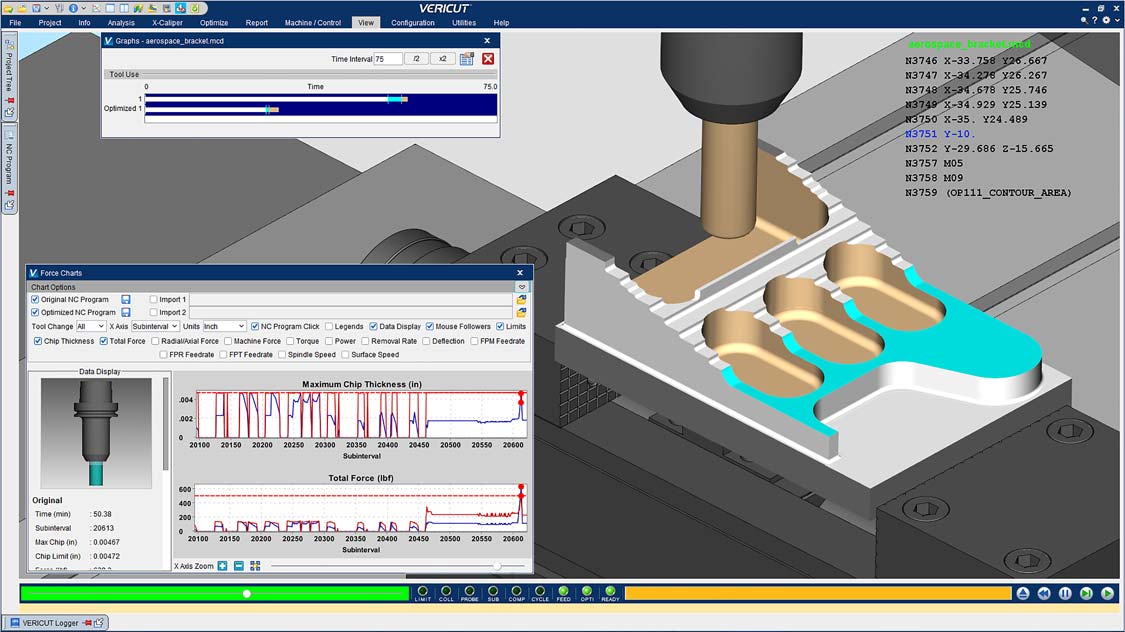

Stop throwing your profit in the swarf bin and turn back time with VERICUT Force. Do you want to drastically cut your machining costs, ensure faster NC programs and longer tool life? With VERICUT Force optimisation you can have both. Which is why our technical engineers have created our latest blog to explain just how you can optimise your machining feed rates and cutting conditions, to ultimately produce parts faster and cut machining times by 20% or more.

Many users of VERICUT machine simulation software have already seen increased efficiently and productivity offered by VERICUT’s Force module.

What is VERICUT Force optimisation?

Force is a physics-based optimisation method that sets the maximum reliable feed for a particular cutting condition based on 4 key factors:

- The load on the cutting edge

- Spindle power

- Maximum chip thickness

- Maximum allowable feed

With VERICUT Force optimisation you can ensure that your NC programs are fast and efficient. This is done through calculating the contact between the tool and material, cut-by-cut.

Force calculates cutting conditions using specific material characteristics, considering the strength of the material and the effects of friction and temperature. To ensure reliability and efficiency, material characteristics are based on actual cutting trials and not just on the basis of hypothetical calculations. Force calculates ideal feed rates by analysing:

- Tool geometry and parameters,

- Material characteristics,

- Cutting material,

- Detailed cutting-edge geometry

- VERICUT Smart Part Technology.

Force is ideal for difficult-to-machine materials and complex multi-axis operations such as 5-axis flank milling. Once the material has been defined, it can be applied to a wide range of cutting tools and machines in future NC machining operations. VERICUT Force allows programmers to visualise quickly and easily what is happening cut-by-cut in the NC program as the tool contacts the material. It is easy to set up and can also predict tool wear.

Make optimising an NC program rapid and trouble-free

Just when you thought CNC machining couldn’t get any faster. With VERICUT Force optimisation your organisation is guaranteed to benefit from outstanding cycle time savings and improved cutting tool performance. The first users of this technology have already achieved productivity gains of up to 50 percent.

As the final piece of your CNC machining puzzle, VERICUT Force optimisation is key to take your manufacturing to the next level and maximise your capacity.

As well as cutting machining times by 20% or more on cycle times, your organisation will also benefit from extended cutting tool life. Not to mention, savings on consumables, the potential to reduce overtime and eliminate waste and discarded parts.

Further advantages include:

- Charted cutting condition information for NC program analysis

- FAST analysis and iteration for testing various cutting scenarios

- Maximised and more consistent chip thickness throughout the machining process

- Cut-by-cut analysis of the interaction between the cutting tool edge and the material

- Prevention of undesirable cutting conditions like excessive force, HP/Torque, and tool deflection

Don’t just take our word for it, David Magnall, Innovation Partnership Manager, SECO said of FORCE:

“The Force software does some really clever stuff and the support that we get from the CGTech team is second to none. If you are going to pick a company to work with as a partner these guys are it, they really are. They understand the collaborative approach as a pro-active way of working and addressing the issues faced by industry.”

Jason Mills, Engineering Manager, Advanced Manufacturing (Sheffield) Ltd (AML) said: “We’ve seen up to 40% more tool life and 30-40% savings in machining cycle time when using VERICUT Force,” says Jason Mills. “The module is invaluable for our production work as it provides us with a competitive edge. It’s quite easy to use and understand. We simply pick the material from the database and input the cutter geometry, which we get from the tooling manufacturer. Force then does its calculations in the background.” Did you know you can also use our savings calculator to determine your machining savings?

Work smarter not harder with VERICUT Force optimisation

Most users see a return on investment in just 3-6 months on VERCIUT Force, it is also the easiest to set up in the industry. Working with any tool, material, CAM system and any NC program, Force optimisation is proven to enhance your machining and production.

VERICUT is the industry standard for CNC simulation, verification and optimisation. It is used globally across all industry sectors including aerospace and defence, automotive and autosport, oil and gas, energy, medical, consumer goods and mold production.

Investing in VERICUT is the start of a partnership with one of the world’s leading manufacturing software vendors. Get in touch today to talk to our friendly team and request a demo: https://cgtech.co.uk/vericut-save-time-money

Schedule a Demo or Request a Benchmark

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan