Innovating and gaining a competitive edge in aerospace means meeting increased demand and tight timelines with high quality parts. VERICUT is the key to machining aerospace parts quickly and with confidence.

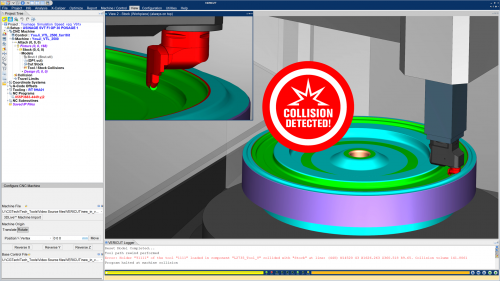

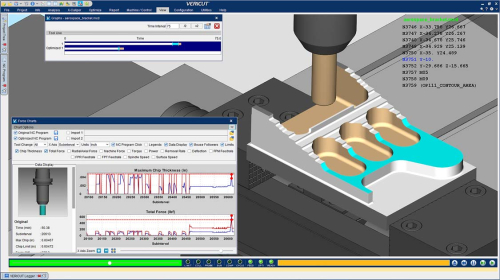

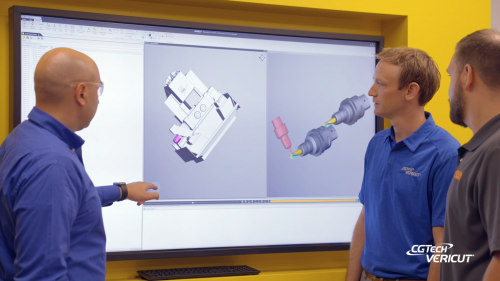

Verify and validate your NC program to prevent collisions or other issues before running it on your machine. VERICUT allows you to reduce or eliminate the manual prove out process, freeing up machine time to run more parts. VERICUT simulates all types of machine tools such as traditional milling and turning machines, composites, and hybrid CNC machines.

Benefits of aerospace CNC simulation

Explore Resources and User Stories

-

Castle Precision Engineering User Story

"When manufacturing high-value components for such critical applications, we need to have confidence that we’re using the very best tools for the job, and VERICUT delivers." - Castle Precision Engineering

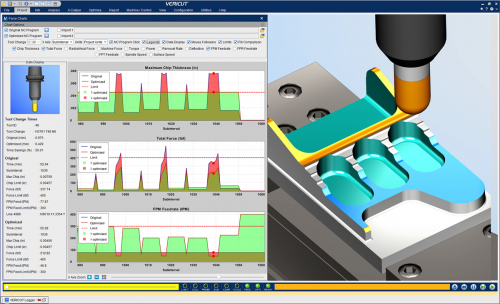

Glasgow-based Castle Precision Engineering has been an advocate for the use of VERICUT CNC simulation software on its shopfloor for many years, protecting high value customer components as well as its own advanced machine tools. More recently the company has embraced the efficiency and productivity gains offered by the FORCE module of the software.

Learn more about how Castle Precision Engineering uses VERICUT Force to improve productivity and gain efficiencies.

-

Advanced Manufacturing (AML) User Story

VERICUT from CGTech is a key component of business success at this rapidly expanding precision machining company, which serves a plethora of customers in sectors such as aerospace, energy and defence. More recently, AML has embraced the efficiency and productivity gains offered by VERICUT’s Force™ module, which is driving tool life gains. Read about how VERICUT's Force Optimization module has helped them achieve a 30-40% reduction in machine cycle times.

-

RO-RA Aviation Systems GmbH User Story

As an aerospace supplier, RO-RA Aviation Systems GmbH is very successful, especially in the production of complex, high-precision and difficult-to-machine components. With demands for high quality components, it is essential that processes are safe and stable. For maximum process reliability and the best possible performance, RO-RA uses VERICUT CNC simulation, verification and optimisation software, including the VERICUT Force milling module. Read about how VERICUT's Force Optimization module has helped to achieve no more machine crashes and time savings of up to 25 percent per component.

-

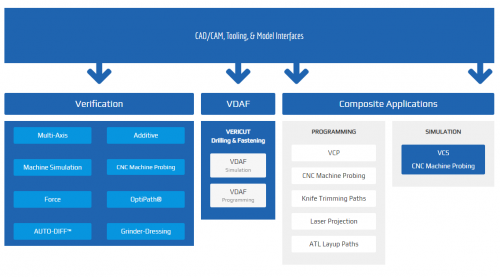

Explore Our Full Product Line

VERICUT offers solutions in machine simulation, verification, optimization, and more. Find the right modules to protect your CNC machines while increasing throughput.

-

VERICUT Force Optimization

VERICUT Force Optimization optimizes new and existing NC programs according to changes in cutting conditions. Protect your CNC machines and extend your tool life; watch the user story from Sandvik Coromant Mebane.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan