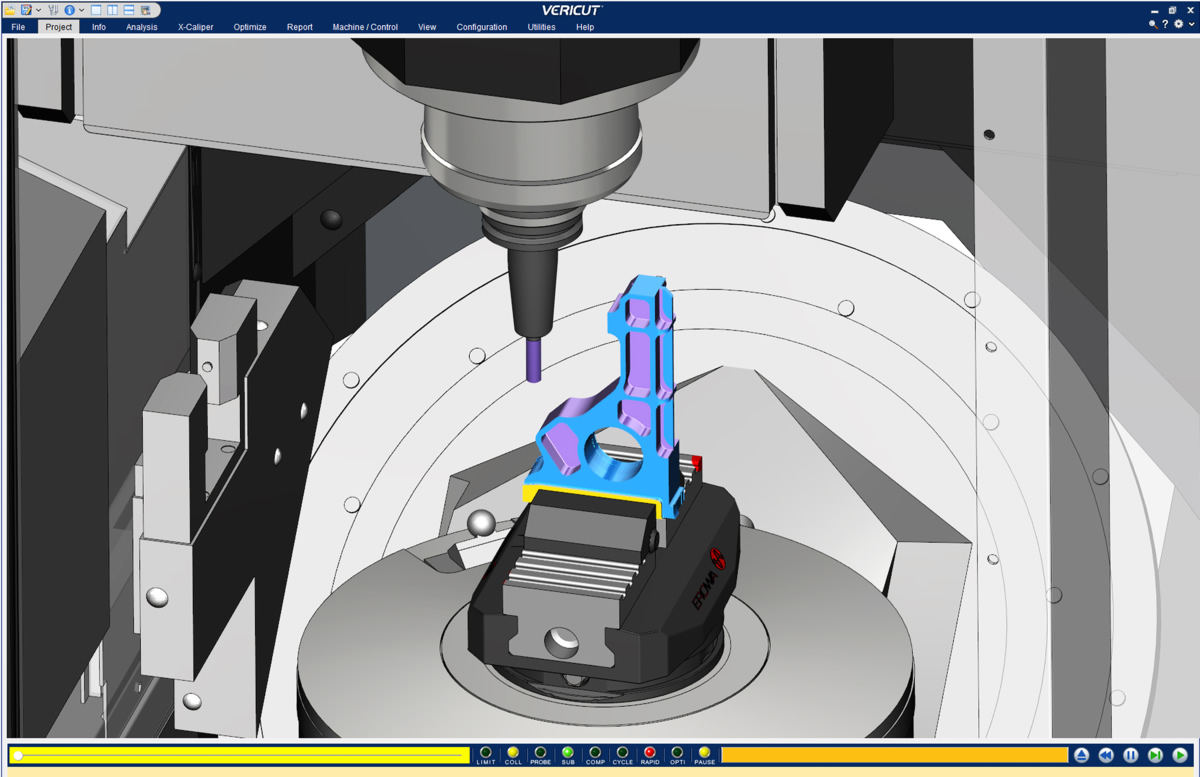

CNC-Machine Simulation

VERICUT enables you to perform realistic 3D simulation of entire CNC machines, just like they behave in the shop, with the most accurate collision-detection available. VERICUT Machine Simulation software supports G-codes and

- Multi-axis support for milling, drilling, turning, grinding & EDM machines

- Simultaneous mill/turn on different spindles and workpieces

- Machines with multiple synchronized CNC controls.

- Auxiliary attachments: tail stock, steady rests, part catchers, bar pullers, etc.

- Automatic workpiece transfer to pick-off or sub-spindles

Superior Collision Checking

VERICUT features the most accurate collision checking available. Rather than just checking points along a path, VERICUT checks along the entire path of travel by sweeping through space. You don’t have to specify a “step size” tolerance that can slow the simulation if too small or miss the collision if too large!

With VERICUT CNC Simulation you can:

- Simulate traditional and multi-axis (4, 5 or more) CNC machines

- Help to avoid CNC machine collisions and safety distance problems

- Reduce the time it takes to implement new CNC machines

- Provided clear instructions for the operator on new NC programs

- Improve process efficiency

- Improve operational safety

- Enhance presentations and documentation

- Train programmers and operators without using production time or risking collisions

Emulation of CNC control logic and G-code support

VERICUT accurately emulates CNC control logic. Each control in your shop can be accurately simulated to account for different types of machines, programs, parts, and functions. You get the flexibility to customize controls.

Using pull down dialog boxes, G-code characters and numerals are defined in a logical “word/address” format, then configured to call CGTech action macros which simulate control functions.

The control logic also supports conditional checks (other codes in the block, current variable values, machine states, etc.) that can alter how the word/address is interpreted.

VERICUT includes a library of flexible, easily modifiable controls from manufacturers such as:

- Heidenhain

- Fanuc

- Mazatrol

- Bosch

- NumeriPath

- Yasnac

- General Electric

- Siemens

- Fadal

- Phillips

- Allen-Bradley

- Cincinnati Milacron

- Okuma

VERICUT supports even the most complex applications, such as:

- Automatic part transfer between fixtures

- Facing head (or “programmable boring bar”)

- Mill/turn machining center’s multi-channel programming/synchronization

- CNC controls which allow programming of the tool axis using IJK tool axis vectors

- Turning operations which are not symmetric about the lathe spindle

- Parallel kinematics machines such as the Tricept head

- Multi-axis waterjet cutting operations

- Material removal for gear hobbing and synchronizes the tool spindle with part spindle

- Auto-fastener programming and simulation

Siemens 840d

%SPF8000

$P_UIFR[1] = CTRANS()

$P_UIFR[2] = CTRANS(X,22.5, Y,22.5, Z,145)

$P_UIFR[3] = CTRANS(X,45+22.5*COS(30), Y,22.5,

Z,145+22.5*SIN(-30)):CROT(Y,30):CROT(Z,45)

T1 M6

D1 S1559 F1000 M3G0 Z200

$P_IFRAME = CTRANS(X,22.5, Y,22.5, Z,145);

M98 PR101

G54

G0 Z250

B30

TRANS

G56

M98 PR101

FANUC 30i

O20001

WHILE[#2LE270.]DO1

G65 P102 B#2 H#102 S5500 C83 Z.45 F10.

G65 P103 B#2 H#102 S5500 C83 Z.45F10.

#2=#2+90.

END1

M98 P9000

G10 L2 P2 X23.45 Y3.334 Z0.1

N300 T#103 T#104 M6 (3/8 2FT EM)

#7=#103+200

#2=0

WHILE[#2LE270.]DO1

Heidenhain TNC530

0 BEGIN PGM NONAME MM

2 L B+0 C+0 F MAX

3 TOOL CALL 1 Z S4500

4 CYCL DEF 19.0 WORKING PLANE

5 CYCL DEF 19.1 A-90 B+0.0 C+180

6 L B+Q121 C+Q122 F MAX

7 L X+0.0 Y+20 Z+50 R0 F MAX M03

8 L Z+50 R0 F MAX

9 L Z+2 R0 F MAX

10 CYCL DEF 200 DRILLING ~

Q200=2 ;SET-UP CLEARANCE ~

Q201=-9.9 ;DEPTH ~

Q206=600 ;FEED RATE FOR PLNGNG ~

Q202=5 ;PLUNGING DEPTH ~

Q210=0 ;DWELL TIME AT TOP ~

Q203=+0 ;SURFACE COORDINATE ~

Q204=2 ;2ND SET-UP CLEARANCE ~

Q211=0 ;DWELL TIME AT DEPTH

11 L X+0.0 Y+20 R0 F MAX M99

12 L Z+50 R0 F MAX

13 CALL LBL 99

14 CALL LBL 54

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan