Simulate Large Scale Additive Manufacturing (LSAM) Machines with VERICUT

CGTech has partnered with Thermwood to give simulation capability for large scale additive manufacturing machines. It will support both the additive 3D printing and subtractive machining capabilities of Thermwood's LSAM machines.

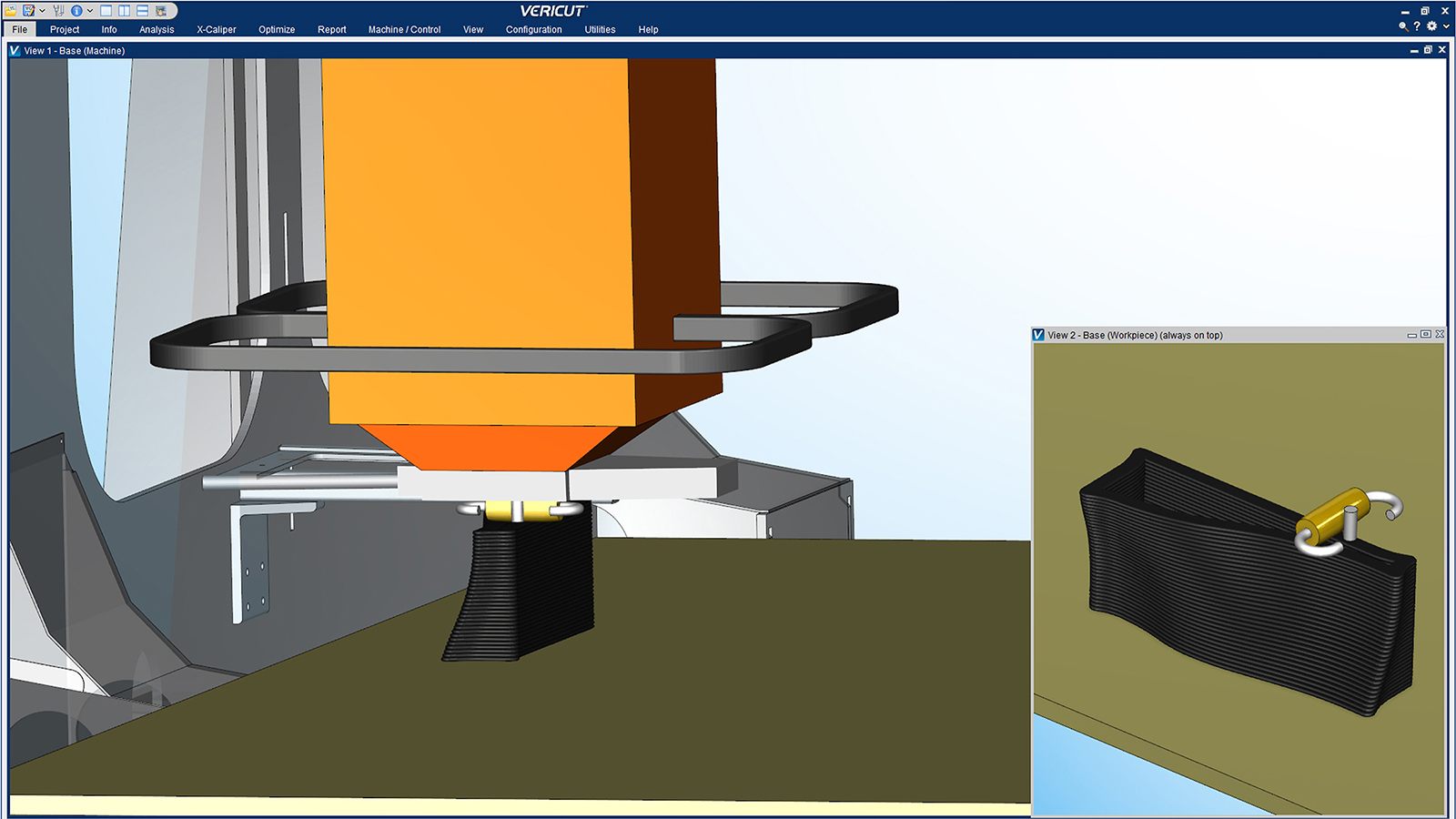

LSAM is a piece of technology for large scale 3D printing of thermoplastic polymers. The Thermwood-developed system uses unique patented technology to produce the highest quality thermoplastic polymer printed structures available. The machines feature both additive and subtractive heads to accommodate printing.

The printing uses a trimming technique called “near net shape.” This means that the object gets printed slightly bigger than the final size before it is trimmed down.

Thermwood recently introduced a new LSAM machine, called LSAM MT (Moving Table). The innovative new machine can print objects with complex shapes thanks to its versatility and offers new advantages in applications.

LSAM MT features a single fixed gantry which is mounted over a moving table. Typically, LSAM MT comes at a dramatically lower price than the standard LSAM system. Both systems can process elevated temperature polymers which are ideal for autoclave capable tooling or compression moulds for thermoset materials.

Why simulate LSAM machines

The CNC (Computer Numerical Control) simulator, verification, and optimization software VERICUT simulates all types of additives, and hybrid manufacturing processes. This helps to verify that the finished part matches the intended engineered design.

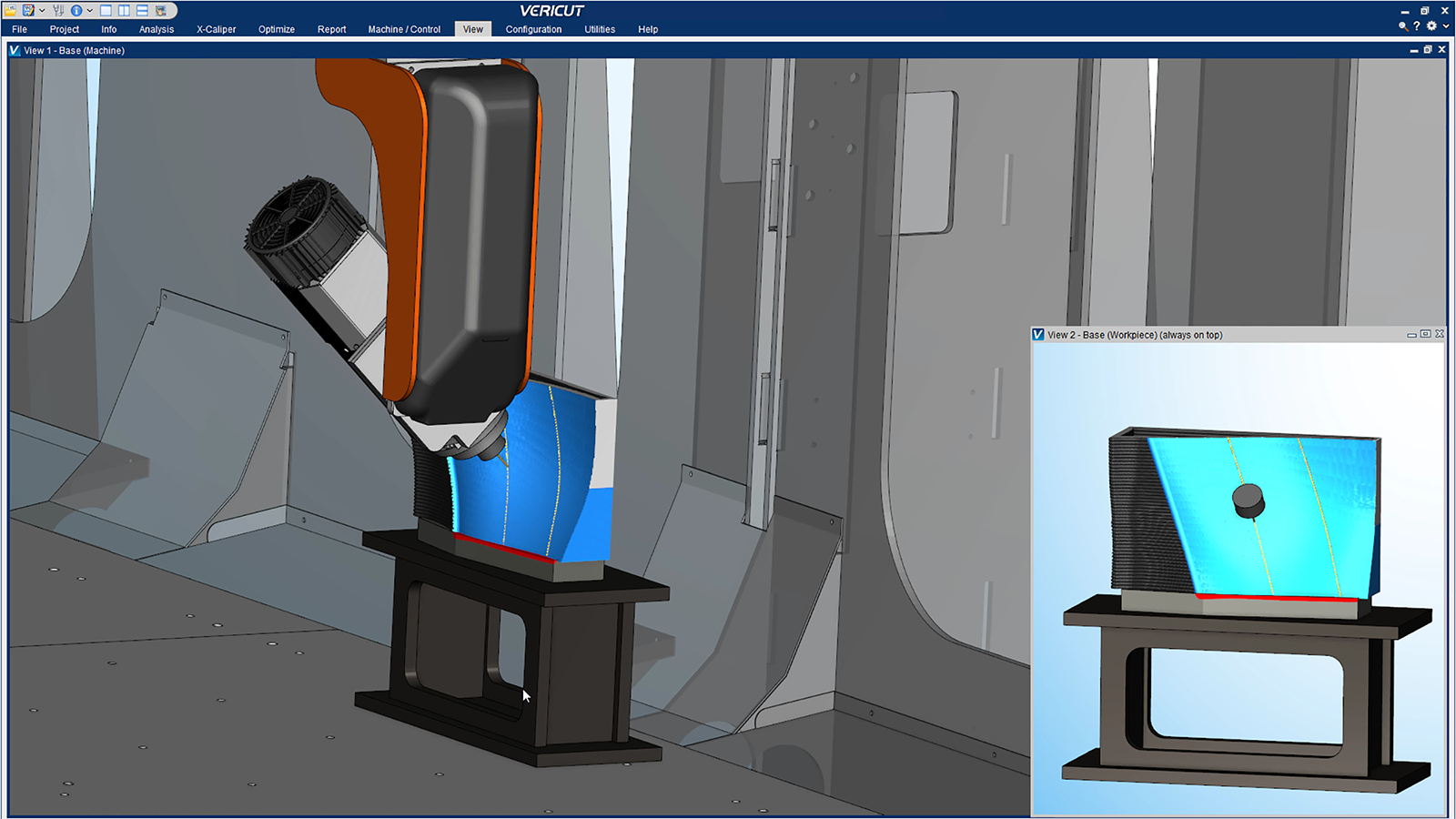

With the help of VERICUT, programmers and operators see exactly how machines behave. This includes seeing any unexpected motions, incorrectly used additive or machining functions, or potential machine crashes. This all happens before they can occur on the real machine.

VERICUT’s Additive module simulates both additive 3D printing and traditional machining capabilities of hybrid CNC machines. This helps to verify that the full manufacturing process works, and the finished part matches the intended engineered design.

VERICUT simulates adding or cutting which makes it the perfect solution for verification optimisation of Thermwood’s industrial LSAM machines.

Using simulation software on LSAM can help to relay training data too. This can help to troubleshoot any issues and streamline integrations.

Simply put, VERICUT is the most comprehensive software ‘insurance policy’ you can have for these types of CNC machines.

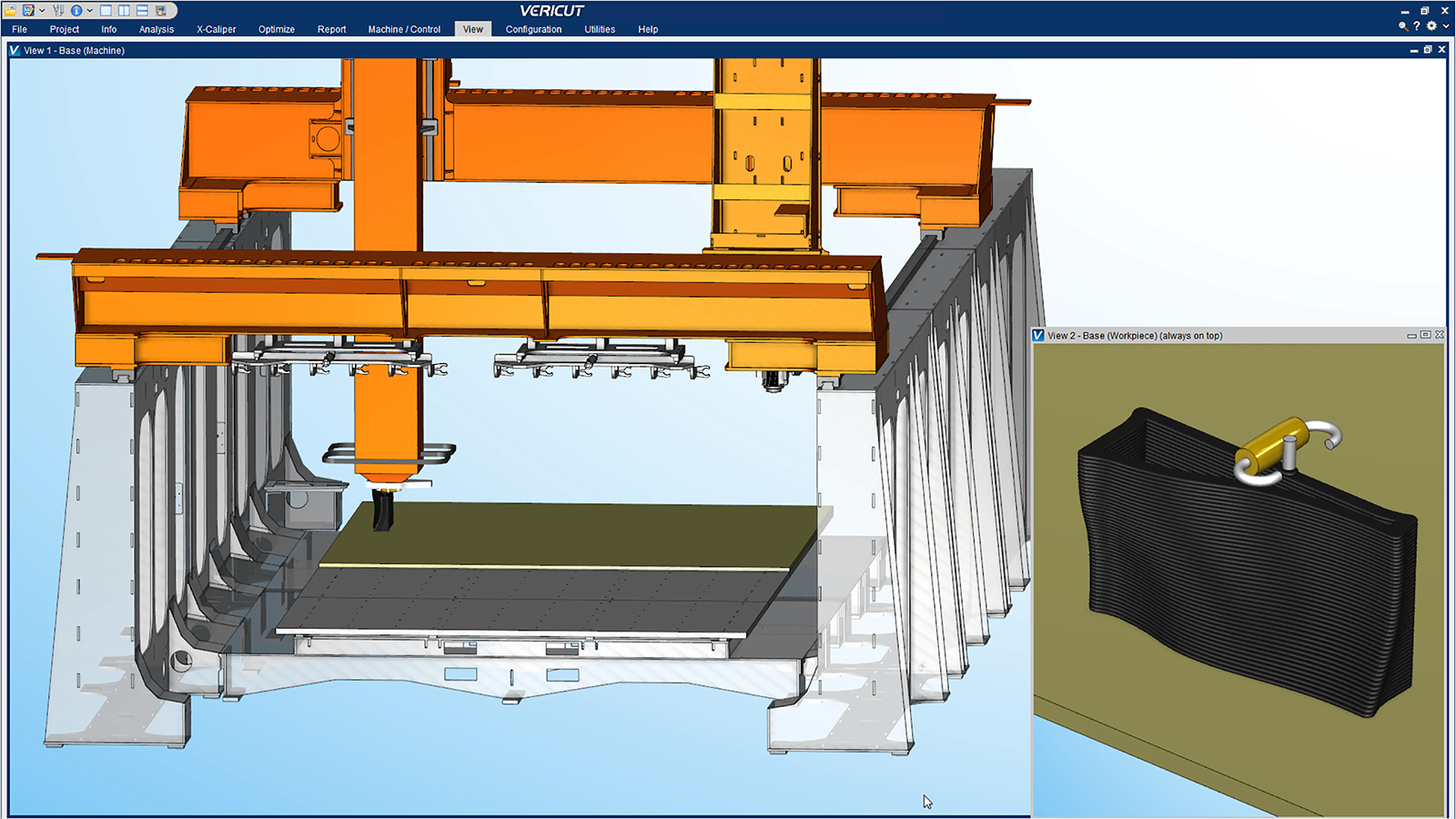

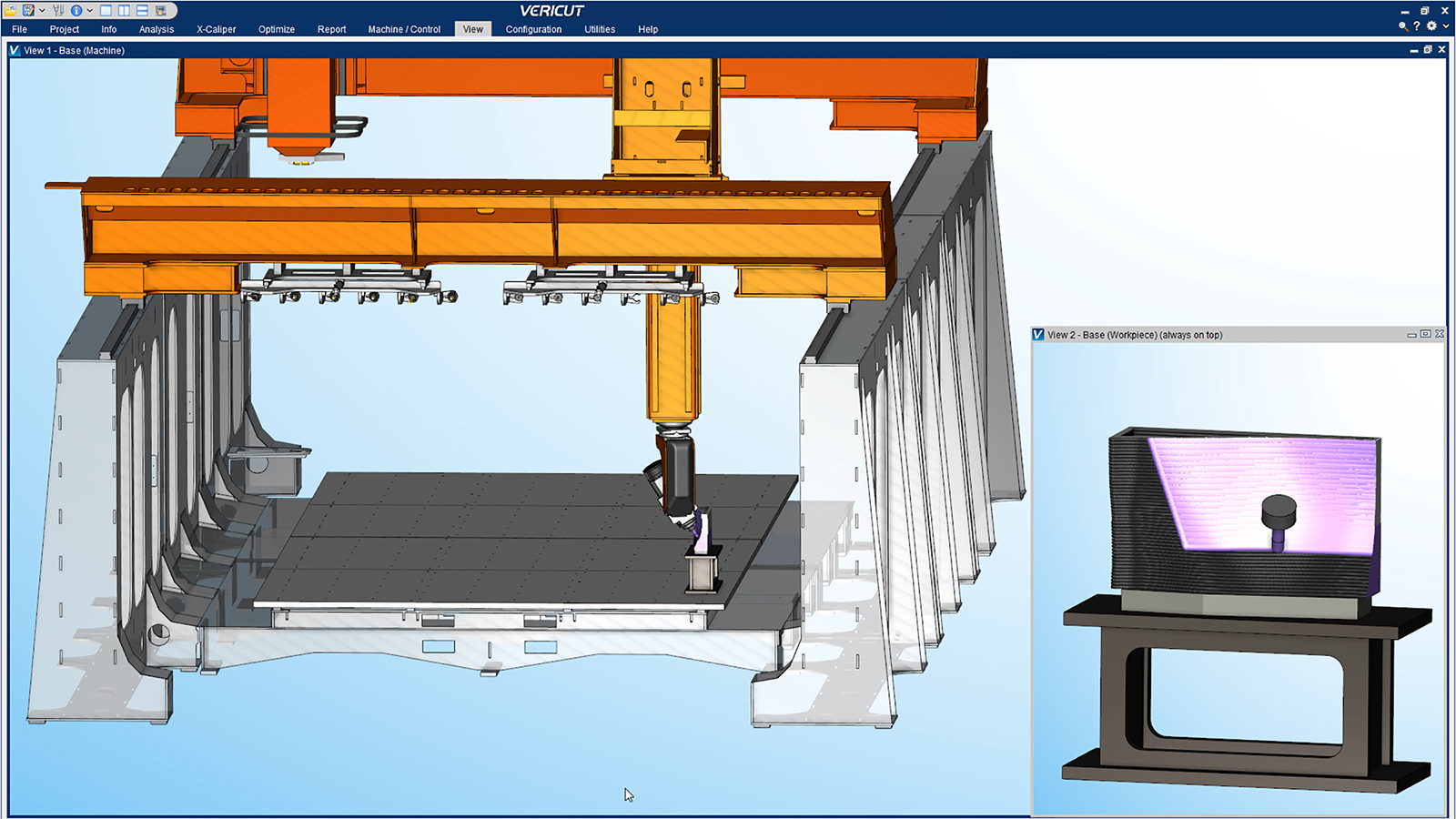

Machine simulations using both the additive (left) and subtractive (right) heads of the dual gantry machine model can be seen below.

Thermwood is the oldest manufacturer of highly flexible, three & five axis high-speed machining centres. It has become the leader in LSAM of thermoplastic composite moulds, tooling, patterns, and parts with its machines.

Learn more about Thermwood’s LSAM machines or contact us to learn more about VERICUT for additive and hybrid machines.

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan