An Example to Follow

Brawo boasts a decades-long specialization in the field of mechanical machining for third parties.

Mauro Pini, Engineering Manager, and Research & Development Manager, of Brawo S.p.A., speaks of exasperated technology. But he does not speak about technology negatively. Indeed, this 'exasperated' technology, brought to the highest level, is the main tool that companies can use today to face an increasingly competitive global market. With its decades-long specialization in the field of mechanical machining for third parties, Brawo knows something about being competitive. "In the past, the location of a company was crucial, but that is no longer the case," Pini tells us. “Today most companies are multinational, with production sites all over the world. We have factories in the United States which is a great help, especially for aspects related to logistics and the performance of the financial market, even if they are not decisive factors. Making great investments makes it possible to maintain a very high level of technology in which we have to aim to compete. " And in fact, on a total turnover of 90 million euros, Brawo invests between 10 and 15 into its technology each year. We are talking about new machinery which is often very complex, but also of software, such as the VERICUT simulation and verification application that is created and distributed by CGTech in California, with Italian headquarters in Treviso.

Ruthless Competition

Part of HUG S.p.A. Group - Holding Umberto Gnutti and with a staff of about 350 people, Brawo mainly deals with hot forging of brass and aluminum, heat and surface treatments, and chip removal processes. “Our reference market is global”, explains Mauro Pini, “and ranges from the medical-health sector to welding to food & beverage. When we talk about mass production, and therefore of numbers ranging from tens of thousands to millions of pieces, we inevitably end up having to face ruthless competition, and the biggest challenge we face is to keep up the quality level of production." The HUG Group is a holding company with a turnover of around € 415 million, which includes six companies: Almag, Lofthouse, Berna, Brawo S.p.A., Brawo USA and Emmebi. The latter, in particular, specializes in the production of equipment for the Group companies and works closely with Brawo, for which it also produces molds.

A Decisive Choice

In 2004, Brawo decided to anticipate to the design phase, and therefore before the real production, the examination of all the possible defects caused by errors in the programming of work cycles and equipment. An important choice, dictated by a real need, but also forward-looking if evaluated in hindsight. "Without having the possibility of carrying out simulations in an embryonic phase - before the beginning of the actual production cycle - we could not be sure that the final machined part was perfectly in line with requirements," Mauro Pini explains. "But above all, we realized that thanks to virtual simulation, it became possible to reduce the testing times of the machine programs and almost completely reduce human error. If the latter had not been corrected in a virtual environment, it could have led to collisions with modest, but significant damages. Instead, in a virtual environment the costs of the crashes are obviously zero."

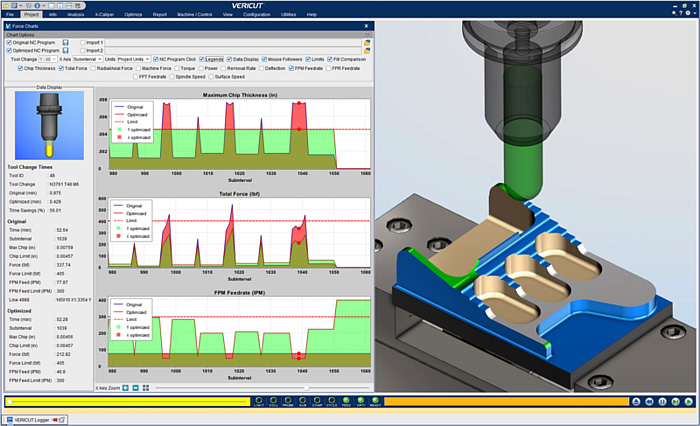

And so, to cope with this imminent need, Brawo decided to integrate VERICUT into its production process. The software simulates the exact real-world machining environment, including rapid movements, multi-axis movements, multiple placements, complex tool shapes, collisions of tools and tool holders, machine kinematics, complex control functions, and so on.

Quality Advantages

“Today all Brawo's NC programs are certified with VERICUT before entering the shop floor and being run on the machine,” continues Pini. "This applies to both the tooling and the programs for mass production. Also, those intended for transfer machines, machining centers and workstations."

Like Brawo, Emmebi has also gone in the same direction, implementing simulation with VERICUT in all of its production processes. "Programs for the processing of very varied shapes such as those of the molds", explains Mauro Pini, "consist of hundreds of thousands of program lines. This means that it would be practically impossible to simulate them block by block on the machine. Furthermore, we must consider that chip removal is a very sophisticated and delicate process, and it is essential to be able to transfer a congruence of tool movement to steel so that the final result is of excellent quality. VERICUT is a precious help in this area as it allows you to optimize the tool path even in terms of quality, effectively eliminating any possible defects that would be unacceptable on the surface of a mold." A further advantage, the latter, which is added to those already mentioned. "I can say that the evolution of VERICUT," adds Pini, "went hand in hand with the increase in the complexity of the machines that we gradually introduced into our production plants, and this has been essential for us.”. Not to mention that the continuous innovations of the software have gone far beyond mere kinematic simulation, involving new areas, but always absolutely relevant. And the Force module is a concrete example of this.”

Quality Machining

Pini dedicates his last thoughts to VERICUT Force, the new software module for optimizing NC programs. "As far as obtaining high-quality machining is concerned," he explains, "VERICUT Force allows you to move to the next level: that is, to dynamically keep tool deflection under control when removing material, and to avoid force peaks that can be generated on the tool which would cause imperfections on the surface of the mold, but also could also have repercussions on the tool life itself ".

The Main Features of VERICUT Force

The new VERICUT Force module allows you to optimize tool feedrates, based on the experimental characterization of the material to be processed, without altering the trajectory provided by the CAM software. In addition to the tool path, the software also controls the physical properties of parameters related to force, spindle movement, chip thickness, and removal rate.

Article translated from Open Factory Edizioni Srl – Tecnè © 2020

https://cgtech.co.uk/component/k2/item/398-brawo-s-p-a.html#sigProIdfdc74843fe

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan