Go with the Flow

Industrial flowmeter and fuel transfer pump manufacturer brings offshored work back to the US

When a company spends several million dollars on a flexible manufacturing system (FMS), one that’s expected to compete with offshore suppliers and revitalize the shop floor in the process, it’s important to make the most of the investment. Above all, there must be some assurance it will never crash.

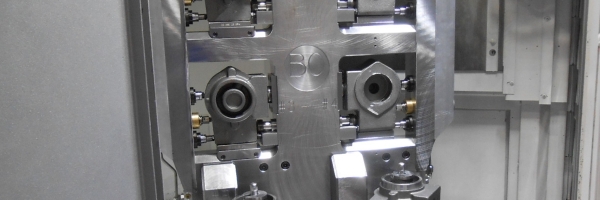

Great Plains Industries Inc. (GPI) has taken steps to do just that. Beginning in June of 2015, GPI kicked off “Project One,” the installation of four MB-500H Okuma horizontal machining centers equipped with 15,000 rpm spindles and 218 tool matrices, together with an integrated Palletace 60-pallet M-1100 material handling system built for Okuma by automation provider Fastems. The FMS is equipped with spindle probing, tool life management, remote monitoring, and every lights-out bell and whistle needed to maximize productivity.

The safety net sitting beneath it all is VERICUT machine simulation and optimization software from CGTech, Irvine, Calif.

Chuck’s Legacy

GPI had humble beginnings. Charles Peer was a mechanical engineer working at Beech Aircraft when the 1968 recession hit. He and two of his coworkers took their unemployment checks and went into business for themselves. Working from Peer’s basement, the fledgling company designed a hot air bypass valve, or H-Valve, for controlling Learjet cabin temperatures—unfortunately, the aircraft industry “went in the dumper” soon afterwards, and Peer and his colleagues had to diversify quickly. By 1971, they were taking their first orders for the “Comfort King,” an evaporative cab cooler for the booming farm machinery market, and from there it was a short leap into fuel pumps and flowmeters. GPI incorporated in 1972, and soon established itself as a market leader in fluid management and instrumentation systems.

By 2011, just before it’s 40th anniversary, GPI passed the $40 million sales mark. The company was 200 employees strong by then, and boasted three divisions and over one hundred products. Unfortunately, Charles Peer wasn’t there to see it—he died suddenly in 2008, leaving ownership of the company to his family. He left behind a legacy of integrity, solid customer relationships, and strong work ethics.

Machine shop manager Jean Alcala was there for that sad day. “I’d been working at GPI a couple of years at that point. We’d made a good deal of progress as far as modernizing our workholding and increasing throughput, but there was only so much we could do with standalone machine tools. When the shop couldn’t keep up with increasing demand, the decision was made to outsource all our cast iron machining to China.”

A Turning Point

GPI eventually hired a new president and CEO, Vic Lukic, a former executive at global pump manufacturer Grundfos. Lukic introduced Lean principles such as Kaizen and Six Sigma to the company, his goal to achieve zero defects. GPI was struggling with quality and supply chain issues at that time with its overseas suppliers, so during a management meeting, Lukic and the team agreed to investigate the possibility of bringing their outsourced work back home.

“The problem with offshoring is that, when there’s a problem, you can’t send it back,” says Alcala. “Now you’re faced with rework and late delivery of products. That’s why we looked at the FMS, to continue down the path of business process improvement that started with the Kaizen events and other quality initiatives—we knew having our own in-house flexible manufacturing system would eliminate nonconformance, provide better service to our customers, and help optimize the organization overall. At the same time, we knew we needed a tool that would ensure there aren’t any issues, one that would actually monitor and validate the machine’s kinematics in real time before cutting any metal. That way there’s no chance of harming an operator, or wrecking a $30,000 spindle and being down for a week while it’s being replaced. VERICUT is that tool.”

An Experienced Viewpoint

Programmer Matt White, a friend of Alcala’s and someone who followed the activity at GPI closely for several years before joining the team, agrees. White has used VERICUT for nearly ten years, and says the software prevents mistakes (even though his are few and far between, he laughs). “Even programmers mess up sometimes. When they do, VERICUT is there to prevent catastrophic damage to expensive equipment. It saves us in so many ways—money for repairs, machine availability, operator injury, tool damage, and ultimately time. That’s the one thing we can’t get back.”

Just as important is program accuracy, says White. By using VERICUT’s AUTO-DIFF function, which compares the part’s CAD model to the actual toolpaths used to machine it, errors such as gouging and out-of tolerance conditions are detected in advance, avoiding costly rework after the fact. And since toolpaths are graphically displayed, it’s very easy for the programmer to minimize idle time and reduce inefficient code.

GPI is also making VERICUT functionality accessible to the people on the shop floor. VERICUT Reviewer, a license-free download available on the CGTech website, gives machinists the ability to see what’s going to happen before it pushing cycle start: no more surprises, or nervously hovering over the emergency stop button while the first part is being cut.

“One of the other things that VERICUT does is give an accurate cycle time representation,” White points out. “Since you’ve defined the kinematics of the machine tool—acceleration, deceleration, rapid traverse rates, workspace dimensions and tool lengths—we can actually plan and budget the manufacturing of any new parts, or any existing parts that we plan to run across any of our machines.”

Moving to Flexibility

GPI split Project One into two phases. The first phase is nearly complete, with two machines coming online in September of this year. The second pair will be delivered early in 2016 and go into production shortly after. Alcala and White both agree: it’s been a lot of work.

“We opted to go with two machines at first,” says Alcala. “This gives us a chance to figure out our processes and make sure everything is bullet proof before introducing the next set of machines. We’re starting with our 25 GPM housing, which on the website is called the PRO25-012, and then by March we expect have all of our cast iron running in house.”

Implementing FMS is not simply a matter of installing the machines. GPI has been on a steep hill of process improvement—they’ve retired their old side-lock toolholders in favor of balanced shrink-fit holders, and worked with a nearby tooling house to design and build a SMED-style hydraulic fixturing system, one that accommodates GPI’s wide variety of products while providing quick changeover between jobs, rigid workpiece clamping, and repeatability.

In-process spindle probing is another new concept to GPI. “There’s so much variation with cast iron parts that we needed a way to automatically find the exact location relevant to the expected geometry,” Alcala explains. “When you have compressed gasoline or diesel fuel running through one of these pumps, you have to maintain minimum wall thickness, otherwise you run the risk of a leak and possibly have a fire or even explosion while the product is in service. So we decided to use a spindle probe to qualify each part at the start of the machining cycle. This assures the casting is where we expect it to be, and compensates the work offset if not.”

VERICUT can also simulate probing cycles. Implementing this feature is another item on the team’s process improvement checklist, but Alcala says it’s a nice-to-have at this point. “It’s something we’re looking at. Our first priority is to avoid causing harm to our employees. Anytime you have to stick your head in the machine to prove out a program, it’s very dangerous. I’ve seen where a retention knob breaks off in-process and the tool is bouncing around inside the machine—imagine what would happen if one of my employees were struck by that. Because of VERICUT, that’s a liability we no longer have. The risk to our workers, our machine tools, our machined parts —VERICUT helps us in every respect, and is a tool that will help us improve our overall situation as a company overall.”

The Big Picture

Success takes far more than foolproof programs, however: it takes a paradigm shift in the way people think. “We have a zero defects mandate from our president,” he says. “The question is, how do you get there? We’re taking a systematic approach to help the organization optimize its underlying processes. We’re embracing Lean principles to achieve a complete process redesign—the blueprint for that is to break down the silos within the organizations in order to work as a cohesive team. We’re going through a lot of changes right now, but it’s all worth it to bring this company into the 21st century.”

Programmer White agrees. “I tell people you’re either moving forward or you’re dying. Anything we can do to streamline our processes or add value to us as a company, that’s what we’re after. VERICUT is worth its weight in gold to us. Avoid just one mistake and the software has paid for itself five times over. I never have to worry about explaining to my boss how a spindle got damaged or we scrapped out an expensive workpiece. It also helps that CGTech is very easy to work with. We have a user group here in Wichita and they’re always good about getting everybody together whenever there’s a new release, to see the changes in VERICUT and keep us current on the latest and greatest technology. From my side, we’ll continue to build on VERICUT and use it for whatever we can. It helps us to make the most of our day, and be very efficient with what we do.”

Article published in Cutting Tool Engineering, December 2015 (PDF)

Germany

Germany Italy

Italy USA

USA South Korea

South Korea UK

UK India

India France

France China

China Japan

Japan